Why a Proper Base for Paving Stones Makes All the Difference

A base for paving stones is the foundation layer of compacted aggregate material—typically crushed stone or gravel—installed beneath pavers to provide stability, support drainage, and prevent shifting or sinking over time.

Quick Answer: What You Need to Know

- Primary Material: ¾-inch angular crushed stone (quarry process)

- Typical Depth: 4-6 inches for patios/walkways, 8-12 inches for driveways

- Key Function: Provides stable foundation, ensures drainage, prevents frost heave

- Essential Steps: Excavate, install geotextile fabric, add base in layers, compact thoroughly

- Critical Factor: Proper compaction (95%+ density) is more important than material choice

If you want a paver project to last, you must start with a solid foundation. Many beautiful patios and walkways become uneven or sunken within a few years because of an improperly installed base.

The base for paving stones serves three critical functions:

- Structural support: It distributes weight evenly across the subsoil, preventing pavers from sinking.

- Drainage management: It allows water to flow away from the surface, preventing pooling that leads to frost heave and deterioration.

- Long-term stability: It creates an interlocking foundation that keeps pavers locked in place, even under heavy traffic.

Think of the paver base as the unsung hero of your hardscape. While the finished surface gets the admiration, what’s beneath determines if your project will last for decades or fail in a season. Without a proper base, pavers will shift with freeze-thaw cycles, sink under foot traffic, and develop uneven gaps. A small investment in doing the base right saves you from costly repairs.

I’m Tim DiAngelis, owner of Lawn Care Plus Inc. Over the past decade, I’ve installed countless hardscapes throughout the Boston Metro-West area, where proper base for paving stones preparation is critical due to our harsh freeze-thaw cycles. This guide will show you how to prepare a paver base that keeps your hardscape looking perfect for years.

Relevant articles related to base for paving stones:

Choosing the Right Materials for Your Base for Paving Stones

Selecting the right materials for your base for paving stones is paramount for durability, drainage, and compaction. In Massachusetts, where freeze-thaw cycles are significant, the right material choice is even more critical to prevent damage and ensure stability.

Common Paver Base Materials: A Comparison

Here are the most common materials we use and recommend:

-

Crushed Stone (Quarry Process / Crusher Run): Considered the gold standard, this is a mix of angular crushed stone (typically ¾-inch down to dust). The varied particle sizes allow for excellent compaction, creating a dense, interlocking, and well-draining foundation. Also known as Dense Grade Aggregate (DGA) or Item #4, it offers superior stability.

-

¾-inch Angular Gravel: This material consists of stones roughly ¾-inch in size with sharp, irregular edges. The angularity allows the stones to interlock when compacted, creating a stable base. Unlike round pea gravel, it provides a solid foundation with good drainage, but it may not achieve the same compaction density as QP without the finer particles.

-

Limestone Screenings: Also called stone dust, these are very fine particles from the limestone crushing process. While it compacts well, it tends to retain moisture, which can cause shifting in a freeze-thaw climate. We recommend mixing it with coarser materials rather than using it as a standalone base.

-

Recycled Concrete Aggregate (RCA): An eco-friendly and affordable option made from crushed, reclaimed concrete and asphalt. RCA offers good stability and drainage, making it a viable alternative to virgin crushed stone, though its quality can vary by source.

| Material | Durability | Drainage | Compaction | Average Cost (per cubic yard) |

|---|---|---|---|---|

| Crushed Stone (QP) | Excellent | Excellent | Excellent | $15 – $30 |

| Angular Gravel | Good | Good | Good | $15 – $30 |

| Limestone | Good | Moderate | Excellent | $20 – $40 |

| Recycled Concrete | Good | Good | Good | $15 – $30 |

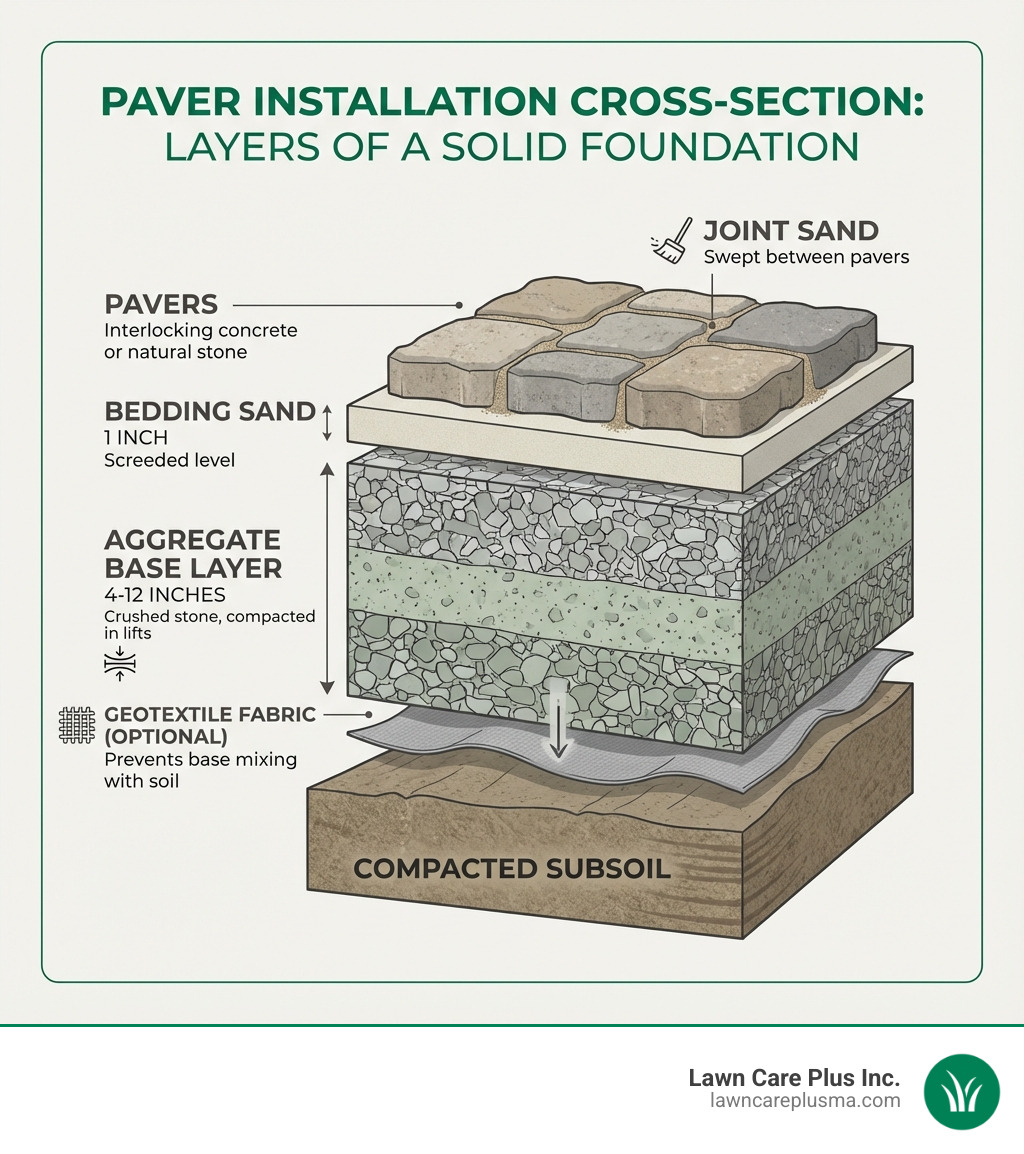

Understanding Paver Base vs. Bedding Sand

It’s common to confuse the paver base and bedding sand, but they have distinct roles.

-

Paver Base Function: The base for paving stones is the primary structural layer, typically 4-12 inches of compacted crushed stone. It bears the load of the pavers and traffic, distributes weight, and provides drainage to prevent sinking and frost heave.

-

Bedding Sand Function: This is a thin (1-2 inch) layer of coarse sand (like concrete sand) laid on top of the compacted base. Its purpose is not structural; it provides a smooth, even surface for laying and leveling the pavers.

The base provides the muscle, while the bedding sand ensures a level finish. You can learn more about these foundational elements in this Paver Base: Your Ultimate Guide.

Factoring in Climate and Cost

The Massachusetts climate, with its harsh winters, significantly impacts base preparation. The freeze-thaw cycle (frost heaving) can destroy an improperly installed paver surface.

-

Climate Considerations: To combat frost heave, a deeper base and adequate drainage are essential. A thicker granular base is less susceptible to frost than the subsoil. This is why a driveway in Needham, MA, requires a deeper base than one in a warmer climate.

-

Material Cost: Costs vary by material, quantity, and location. For a small 100 sq. ft. patio with a 6-8 inch base, materials might cost $400-$700. Most backyard projects can expect to spend $100 to $500 on base materials.

Please note, cost estimates are based on national averages and do not reflect pricing for Lawn Care Plus Inc. Prices can range from $15 to over $120 per cubic yard depending on the material and your location.

Step-by-Step Guide to Installing Your Paver Base

A solid base for paving stones is the backbone of any successful hardscaping project. Whether you’re building a patio in Belmont or a driveway in Canton, preparing the base correctly is where durability begins.

Step 1: Planning, Excavation, and Subsoil Prep

Careful planning and preparation are essential for a long-lasting paver installation.

- Project Layout: Mark the project outline with stakes and string, extending the area about 6 inches to accommodate edge restraints.

- Squaring Corners: Use the 3-4-5 method to ensure square corners. Measure 3 feet along one line and 4 feet along the perpendicular line; the diagonal between these points should be exactly 5 feet.

- Setting the Grade for Drainage: This is critical in Massachusetts. Set a minimum slope of 1% to 1.5% (a 1 to 1.5-inch drop over 10 feet) to drain water away from structures. Use a laser or line level to establish elevations and install any drains before adding the base.

- Excavation Depth: Dig deep enough for the pavers, bedding sand, and base. The required depth depends on the project and soil type.

- Patios/Walkways: A 4-6 inch compacted base is needed. Excavate 6-8 inches below the final grade.

- Driveways: An 8-12 inch compacted base is required. Excavate 9-14 inches below the final grade.

- Clay Soil/Frost Areas: In our climate, you may need to dig deeper to prevent frost heave—up to 14 inches for patios and 18 inches for driveways.

- Subsoil Prep: Clay soils, common in the Boston area, retain moisture and require deeper excavation and geotextile fabric. Compact any recently filled or loose subsoil before adding base material.

For a visual guide, you can refer to resources like this: Follow these steps to create a reliable foundation.

Step 2: Calculating and Installing the Base for Paving Stones

Once excavated and graded, it’s time to install the base for paving stones.

Tools and Materials Needed:

- Shovel and wheelbarrow

- Tape measure and level

- Hand tamper or plate compactor

- Geotextile fabric

- Base aggregate (crushed stone, QP, RCA)

- Bedding sand

Calculating Material Needed:

- Measure the project’s length and width in feet.

- Convert your desired base depth from inches to feet (e.g., 6 inches = 0.5 feet).

- Multiply Length x Width x Depth to get the volume in cubic feet.

- Divide by 27 to convert to cubic yards. Always order a little extra.

- Example: For a 10’x10′ patio with a 6″ (0.5 ft) base: 10 x 10 x 0.5 = 50 cubic feet. 50 / 27 = 1.85 cubic yards.

The Role of Geotextile Fabric:

After excavation, lay geotextile fabric over the subsoil. This creates a barrier that prevents the base from mixing with the soil, which is crucial for maintaining stability and drainage, especially in clay soils.

Spreading and Compacting the Aggregate:

This is the most critical step. Spread the base aggregate (like ¾-inch crushed stone) in 2-3 inch layers, or “lifts.”

- Compact each lift thoroughly with a plate compactor (minimum 5,000 lbs of force is best).

- Make multiple passes until the surface is firm, aiming for at least 95% Proctor density.

- Proper compaction prevents settling. Never install a base over frozen ground, as it will lead to failure.

Step 3: Screeding the Sand for a Level Surface

With the base for paving stones compacted, add the bedding sand for a perfectly level surface.

- Bedding Sand Layer: Apply a uniform 1-inch layer of coarse bedding sand (concrete sand) over the compacted base.

- Using Screed Rails: Lay 1-inch diameter pipes parallel across the base, 4-6 feet apart, to act as guides.

- Leveling the Surface: Shovel sand between the rails and pull a straight 2×4 board across the tops in a sawing motion. This “screeds” the sand, leaving a perfectly flat, 1-inch layer.

- Finishing: Carefully remove the rails and fill the trenches with sand, smoothing the area with a trowel. Avoid stepping on the screeded sand.

- Final Flatness Check: Before laying pavers, check for flatness. Correct any imperfections greater than 1/8 inch over a 10-foot span.

For more information on ensuring proper installation for your outdoor surfaces, you might find our guide on walkways and stairs installation helpful.

Common Mistakes and Pro Tips for a Flawless Finish

With expert advice, you can avoid common pitfalls and ensure your hardscape endures for decades in our Massachusetts climate. We’ve seen many projects fail because the base for paving stones wasn’t prepared correctly.

Mistakes to Avoid When Preparing the Base for Paving Stones

- Improper Compaction: If the base isn’t compacted thoroughly in layers, it will settle unevenly, leading to sunken or wavy pavers. A plate compactor is essential.

- Incorrect Depth: Skimping on base depth, especially for driveways or in frost-prone areas, leads to premature failure as the base can’t distribute weight or resist frost heave.

- Poor Drainage/Grading: Failing to create a proper slope for drainage causes water to pool, leading to erosion and severe frost heave damage.

- Skipping Geotextile Fabric: Especially with clay soils, skipping this fabric allows the base to mix with the subsoil, compromising stability and drainage.

- Using the Wrong Materials: Using round pea gravel or plain dirt will fail. These materials lack the interlocking stability, drainage, and compaction properties of proper aggregate.

Pro Tips for Durability and Drainage

- Install Edge Restraints: These are non-negotiable. Plastic or metal restraints installed around the perimeter prevent pavers from shifting outwards.

- Maintain a Proper Slope: Ensure a consistent slope of at least 1/4 inch per foot (a 1-1.5% gradient) away from structures.

- Compact in Stages: Spread base material in thin lifts (2-3 inches) and compact each layer thoroughly for uniform density.

- Check for Flatness: After compaction, check for dips or rises. Imperfections should be no more than 1/8 inch over a 10-foot run.

- Follow ICPI Standards: Adhering to Interlocking Concrete Pavement Institute (ICPI) guidelines ensures professional-grade results.

- Never Install Over Frozen Soil: Installing a base over a frozen subgrade will cause pavement failure when the ground thaws. Wait for it to be fully thawed.

DIY vs. Hiring a Professional Hardscaper

Deciding whether to DIY or hire a pro depends on your project’s scale, your comfort with physical labor, and your desired outcome.

- DIY Considerations: A small project can be a DIY job if you have the right tools (especially a plate compactor), but it is physically demanding and requires precision. Mistakes in the base are costly to fix later.

- Benefits of Professional Installation: For larger projects, hiring a professional is often best. Professionals like Lawn Care Plus Inc. bring expertise on local soil conditions in areas like Brookline, MA, have the right equipment for efficiency, and often provide warranties. Most importantly, they ensure the base is done right the first time, preventing expensive future repairs.

If you’re considering a hardscaping project in Brookline, MA, or any of our service areas, we’re here to help you weigh your options and provide expert installation. Learn more about our services here: More info about hardscaping in Brookline, MA.

Frequently Asked Questions about Paver Base

How deep should a paver base be?

The depth for a base for paving stones depends on the application and climate. In Massachusetts, where frost is a concern, a deeper base is better.

- Patios and walkways: A compacted base of 4-6 inches is standard.

- Driveways: A deeper base of 8-12 inches is necessary to support vehicle weight.

- Frost-Prone Areas: For our climate, we often recommend a deeper excavation to accommodate more base material (up to 14 inches for patios and 18 for driveways) to prevent frost heave.

What is the best material for a paver base?

The best material is a ¾-inch angular crushed stone, often called “quarry process” (QP) or “crusher run.” This mix of various-sized crushed stone and dust interlocks tightly when compacted, creating a stable, load-bearing foundation with excellent drainage. This is vital for a long-lasting paver project.

Can I put pavers directly on dirt or sand?

No. Laying pavers directly on dirt or a thin layer of sand is a critical mistake that guarantees project failure. Dirt lacks stability and drainage, leading to shifting and sinking. Sand alone provides no structural support and will wash away, causing pavers to become uneven. A proper installation requires a multi-layer system: compacted subsoil, a thick compacted aggregate base for paving stones, and a thin bedding sand layer.

Conclusion: Build Your Project on a Solid Foundation

As we’ve explored, the base for paving stones is the most critical part of your hardscape project. It’s the foundation that provides stability, ensures proper drainage, and protects against the challenging Massachusetts freeze-thaw cycles. Skimping on this step leads to costly repairs and frustration.

Investing in a proper base ensures your patio in Newton, walkway in Hyde Park, or driveway in Dedham will remain level and beautiful for decades. It’s an investment in the longevity and value of your outdoor living space.

For a professionally installed hardscape with a guaranteed solid foundation, the expert team at Lawn Care Plus Inc. is here to help. We bring years of experience and a deep understanding of local conditions to every project, ensuring your hardscape is built to last.