Why Choosing the Right Retaining Wall Blocks Matters

Retaining walls are landscape multitaskers that hold back soil, prevent erosion, and create usable flat space. But a successful wall starts with the right material. Choosing the wrong blocks for retaining wall projects can lead to structural failure or an unsatisfying look.

The main types of blocks include:

- Interlocking Concrete Blocks (SRW): The most popular choice for residential projects. They are dry-stacked without mortar and come in various designs.

- Large-Format Concrete Blocks: Heavy-duty units (weighing 2,200+ lbs) used for commercial sites and very tall walls.

- Natural Stone Blocks: Granite, fieldstone, or limestone offer a timeless look but require professional installation.

Key factors in your decision include wall height, soil conditions, drainage, aesthetics, and whether it’s a DIY or professional job. Most residential walls use interlocking concrete blocks for their ease of installation and design variety. However, walls over 3-4 feet typically require geogrid reinforcement and professional engineering.

I’m Tim DiAngelis, owner of Lawn Care Plus Inc. For over a decade, my team has created durable hardscapes for clients in Greater Boston and Metro-West. We know that proper material selection is the foundation of every successful retaining wall.

Find more about blocks for retaining wall:

Understanding the Main Types of Retaining Wall Blocks

Choosing the right blocks for retaining wall projects is the first step toward a successful landscape feature. The conversation always starts with two questions: what do you want your wall to do, and what do you want it to look like? The answers guide you to one of three main categories.

Interlocking concrete blocks are engineered for stability and are common in residential settings. Large-format concrete blocks are used on commercial sites and for tall walls requiring serious strength. Natural stone blocks offer timeless beauty but require a larger budget and skilled installation.

Concrete Interlocking Blocks (SRW)

Interlocking concrete blocks, or Segmental Retaining Walls (SRW), are the workhorses of residential landscaping. They stack without mortar, relying on weight and locking mechanisms. This flexibility is an advantage during New England’s freeze-thaw cycles, which can crack rigid walls.

- Solid core blocks offer maximum weight, ideal for gravity walls where mass provides stability.

- Hollow core blocks are lighter, easier to handle, and reduce labor costs. When filled with drainage stone, their hollow centers become part of the wall’s drainage system, preventing water pressure buildup—a common cause of wall failure.

These blocks connect via pinned systems or lip systems. A lip system creates a slight backward lean (setback), which is crucial for structural stability. For small walls under three feet, these blocks are designed with DIY installation in mind. However, professional installation is recommended for taller or more complex walls where mistakes can lead to major problems.

Aesthetically, you can choose from split-face blocks that mimic rough stone, tumbled finishes for a weathered look, or smooth finishes for a contemporary style. Colors range from natural earth tones to various grays.

Large-Format Concrete Blocks

When a project demands serious strength, large-format concrete blocks for retaining wall are the solution. These units can be 2x2x4 feet and weigh over 2,200 pounds, making them suitable for commercial applications, tall walls, and areas with high soil pressure.

They feature interlocking grooves and rebar rings for placement with heavy machinery. Their size means fewer seams, creating a monolithic structure ideal for supporting heavy loads like parking lots. Due to their weight, these blocks require professional installation with specialized equipment. Systems from manufacturers like Redi-Rock show the potential of these heavy-duty solutions. For more on our commercial work, see our commercial landscaping page.

Natural Stone Blocks

Natural stone blocks for retaining wall projects offer an organic beauty that concrete cannot replicate. Materials like granite, fieldstone, and limestone provide unique character, with variations in color and texture that improve with age.

Natural stone is exceptionally durable and can last for generations. However, the irregular shapes require careful fitting, much like a 3D puzzle. This complexity means both materials and labor are more expensive. Professional installation is essential to ensure a stone wall is both beautiful and structurally sound. Our team has the expertise to build these walls correctly; learn more on our masonry services page.

How to Choose the Right Blocks for Your Retaining Wall

Selecting the perfect blocks for retaining wall projects means matching the material to your project’s specific demands, from height and soil type to your desired aesthetic.

Project Scale: DIY-Friendly vs. Professional Grade

The wall’s height and complexity determine if it’s a DIY project or requires professional expertise.

For small garden walls under 3-4 feet, lightweight interlocking blocks are a great DIY option. Systems like the Allan Block AB Collection are designed for homeowners, using a dry-stack method without mortar. Manufacturers provide detailed installation manuals to guide you. Even for DIY projects, a proper compacted gravel base and good drainage are critical and cannot be skipped.

Large engineered walls over 3-4 feet, those on steep slopes, or walls supporting heavy loads require professional design and installation. These projects often need geogrid reinforcement, engineered plans, and a permit. The complexity of soil mechanics and proper construction demands expertise. Our hardscaping services can guide you through these substantial projects to ensure a sound result.

Aesthetic Considerations: Color, Texture, and Shape

Once structural needs are met, focus on appearance. The right blocks for retaining wall can complement your home and landscape.

- Style: Match your home’s architecture. A traditional home might suit a rustic fieldstone look, while a contemporary home may call for sleek, smooth-faced blocks.

- Color: Options range from warm earth tones (tans, browns) to cool grays and charcoals. Some blocks offer color blends for a more natural appearance.

- Texture: Split-face blocks offer a rugged look, tumbled finishes provide a softer, aged appearance, and smooth finishes create clean, modern lines.

- Shape: Straight blocks create linear walls, while beveled blocks allow for curves. Some blocks have different faces on each side, offering design flexibility.

See how we’ve applied these principles in our our projects gallery.

Key Features of blocks for retaining wall

Functional features impact performance and ease of installation.

- Interlocking System: Modern blocks lock together without mortar, often using a lip and notch system like Allan Block’s. This creates a stable, unified structure.

- Setback Angle: Most systems incorporate a 6° setback, where each course leans back into the soil. This uses gravity to resist soil pressure and is crucial for stability.

- Hollow vs. Solid Core: Hollow core blocks are lighter and offer excellent drainage when filled with aggregate, which is ideal for preventing water buildup in our Massachusetts climate. Solid core blocks provide maximum mass for gravity walls where weight is the primary stabilizer.

- Block Weight: Standard interlocking blocks weigh around 75 pounds, manageable for manual placement. Large-format blocks weighing over 2,200 pounds require heavy machinery.

Structural Integrity: How Blocks, Drainage, and Reinforcement Work Together

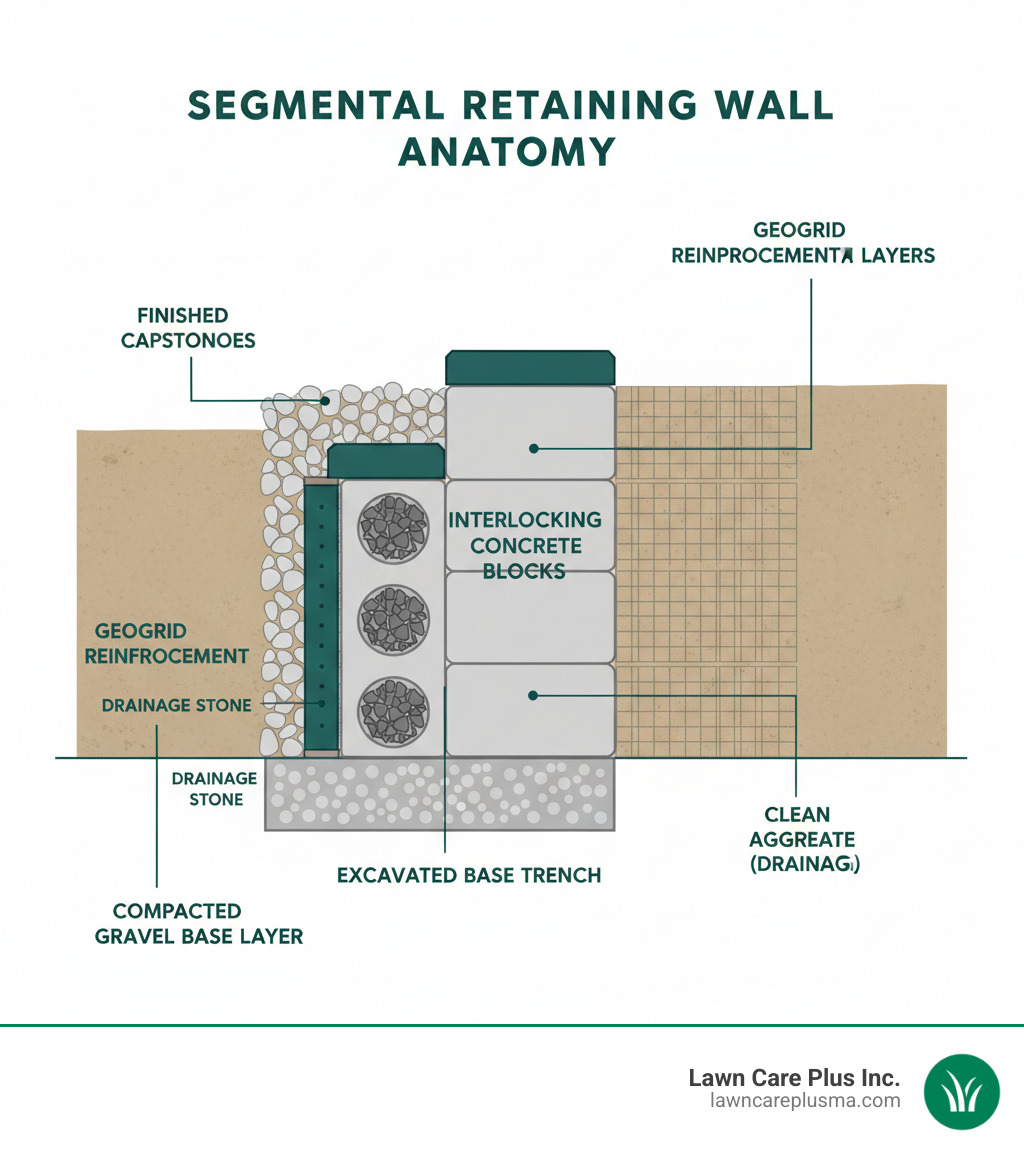

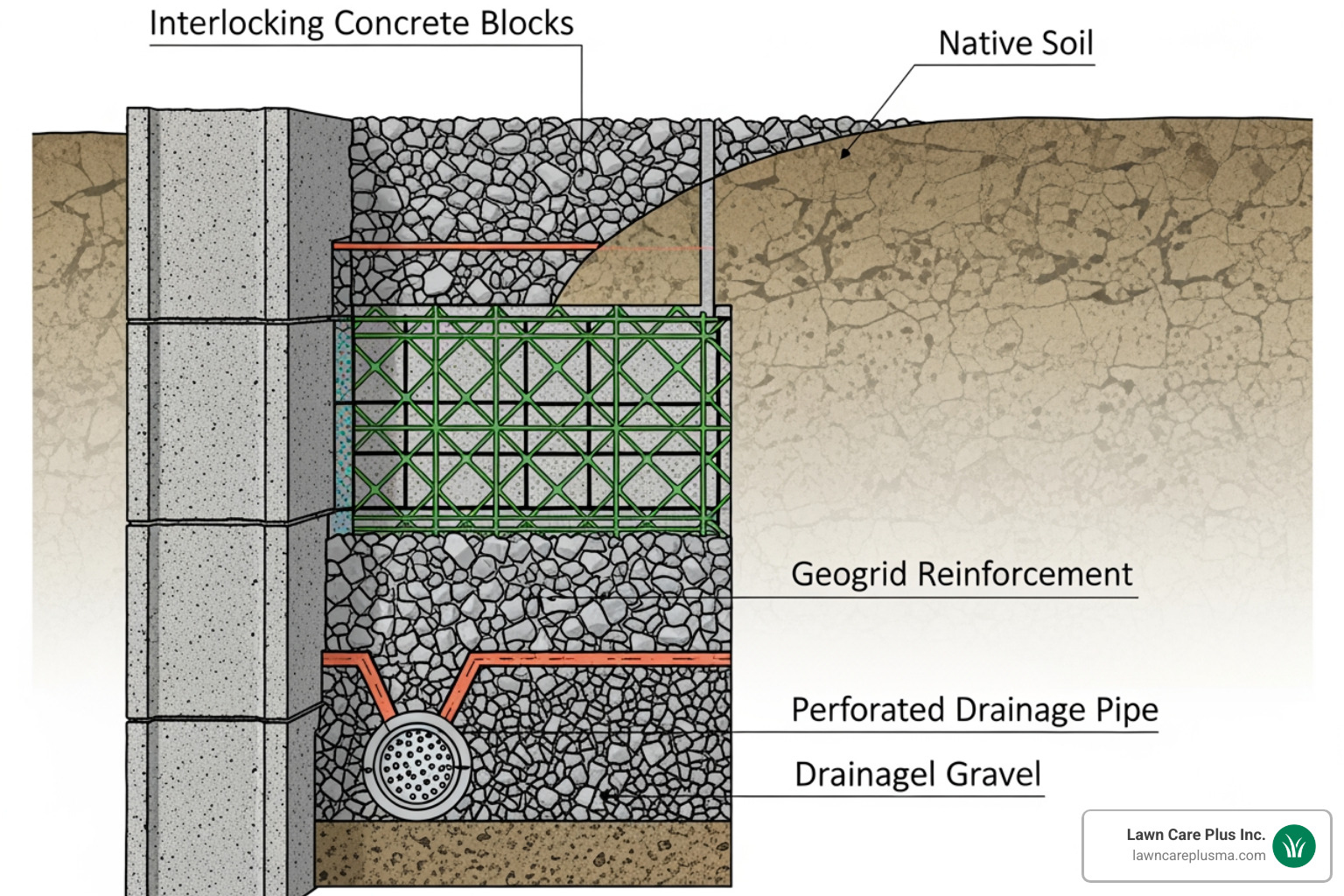

A retaining wall is a complete system, not just a stack of blocks. The interaction between the blocks for retaining wall, drainage, and reinforcement is key to building a structure that lasts, especially in the challenging Massachusetts climate.

The biggest threats to a wall are soil pressure and hydrostatic pressure from water buildup. Managing these forces is critical to prevent failure.

The Role of Drainage and Backfill

Water is a retaining wall’s biggest enemy. Accumulated water creates hydrostatic pressure that can cause a wall to bulge, lean, or collapse.

Proper drainage is essential. This includes grading above the wall to divert surface water and using clean aggregate backfill behind it. This granular material (0.25 to 1.5-inch “wall rock”) allows water to flow through easily instead of pooling. This aggregate should fill the hollow cores of blocks and extend at least 12 inches behind the wall.

For most walls over 4 feet, a perforated drain pipe at the base collects water and directs it away. The hollow core design of many blocks for retaining wall is a key part of this strategy, allowing water to filter down to the pipe and preventing pressure buildup. This is especially important for resisting New England’s freeze-thaw cycles.

The soil behind the drainage aggregate must also be compacted in layers (lifts) no thicker than 8 inches to prevent settling. Unsuitable foundation soils like clay should be removed and replaced with compacted granular material. For technical details, Allan Block’s Retaining Wall Design Details offers comprehensive guidance.

When to Use Geogrid Reinforcement

For taller walls or those under heavy loads, geogrid reinforcement is necessary. Geogrid is a synthetic mesh that extends from the wall back into the soil, anchoring the structure into a larger, reinforced soil mass. This dramatically increases the wall’s strength.

Geogrid is typically required for:

- Walls taller than 4-5 feet.

- Walls with slopes above them.

- Walls supporting surcharges like driveways, patios, or buildings.

The specific type, length, and spacing of geogrid layers are determined by an engineer based on wall height, soil conditions, and loads. These engineered walls require professional design and a permit. The reinforcement is laid between block courses during installation, creating a stable system that resists sliding and tilting. A quality wall system depends on all its parts: good blocks for retaining wall, proper drainage, compaction, and reinforcement when needed.

Budgeting for Your Project: Costs and Maintenance of Blocks for Retaining Wall

Understanding the full financial and time commitment is essential for any retaining wall project. Cost is a primary concern for most homeowners, and the answer depends on several factors.

Disclaimer: The following costs are national averages based on internet data and do not represent actual pricing for Lawn Care Plus Inc. Costs vary significantly based on region, materials, and project complexity. For an accurate estimate for your project in Massachusetts, please contact us for a consultation.

Typical Costs for different blocks for retaining wall

The type of blocks for retaining wall is a major driver of both material and installation costs. Wall size, site conditions, and labor also play significant roles.

- Interlocking Concrete Blocks: Material costs typically range from $5 to $15 per square foot. The total installed cost, including labor, base preparation, and drainage, generally falls between $15 and $50 per square foot. The wide range reflects different finishes and site complexities.

- Large-Format Concrete Blocks: Used for commercial or heavy-duty walls, material costs run $10 to $30 per square foot. Installed costs range from $30 to $90 per square foot or more, due to the need for heavy equipment.

- Natural Stone Blocks: As a premium option, materials cost $15 to $50 per square foot. The skilled masonry labor required brings the total installed cost to $45 to $150+ per square foot.

Factors like complex designs, the need for geogrid reinforcement, poor site access, and extensive excavation will increase the final price. Labor is typically the largest cost component of a professionally installed wall.

Long-Term Maintenance Requirements

A properly installed wall using modern blocks for retaining wall requires minimal maintenance.

Concrete block walls are very low-maintenance. An occasional pressure washing can remove dirt or moss. You may see a harmless white powder called efflorescence, which is mineral salt from the concrete. It can be cleaned or left to fade naturally.

Natural stone walls are even easier to maintain. Their varied textures camouflage dirt, and cleaning is rarely needed. The main task is to prevent vegetation from growing in the joints.

For any wall, periodic inspection is key. Once a year, check for:

- Movement: Any bulging or leaning could indicate a structural issue, often related to drainage.

- Capstones: Ensure they are level and secure to prevent water infiltration.

- Drainage: Look for pooling water behind the wall and ensure the drain pipe outlet is clear and flowing freely after rain.

Catching small issues early prevents them from becoming major, costly repairs.

Frequently Asked Questions about Retaining Wall Blocks

Here are answers to the most common questions we receive from homeowners about retaining walls.

How high can I build a retaining wall without an engineer?

The general rule is that walls under 3-4 feet may not require an engineer, but this is not a universal rule. The actual height limit depends on local building codes, the block system used, soil conditions, and any slopes or weight (surcharges) above the wall. For example, some systems like Allan Block can be built up to 5.5 feet without reinforcement only in ideal conditions. If you have clay soil or a slope above the wall, you will likely need an engineer for a shorter wall.

Always check with your local building department before starting. Requirements vary by town, and it’s better to be safe than to have to rebuild a non-compliant wall.

Do I need a permit to build a retaining wall?

This is closely related to the engineering question. Most municipalities in Massachusetts require a permit and engineered plans for walls over 3 to 4 feet tall. Some towns have stricter rules. The height is often measured from the bottom of the footing, not just the visible portion. There may also be setback requirements dictating how close you can build to property lines. Contact your local building department early in the planning process to understand the specific requirements for your project.

What is the best base material for a retaining wall?

A retaining wall is only as good as its base. The best foundation is a well-compacted granular material, like three-quarter-inch crushed stone. This material compacts well and provides excellent drainage. The base should be at least 6 inches deep for short walls and deeper (8-12 inches) for taller walls or poor soil conditions.

The material must be compacted in layers (lifts) with a plate compactor to achieve a solid, level foundation that won’t settle. A granular base also allows water to drain away, preventing frost heave in winter. Never build on topsoil or clay; always excavate to solid ground and build up a proper compacted stone base.

Conclusion: Build a Lasting Landscape Feature

Choosing the right blocks for retaining wall projects is a balance of structural integrity, visual appeal, and budget. Whether you opt for interlocking concrete, large-format blocks, or natural stone, the success of your wall depends on more than just the block itself.

A properly compacted base and an effective drainage system are the non-negotiable fundamentals. These elements are what separate a wall that stands strong for decades from one that fails after a few seasons. A well-designed retaining wall can transform a challenging slope into a beautiful and functional outdoor space, adding value and structure to your property.

At Lawn Care Plus Inc., we’ve installed countless retaining walls across the Boston Metro-West area. We are dedicated to building landscapes that not only look great but perform beautifully for years, withstanding New England’s demanding climate.

If you’re considering a retaining wall, we can help you explore your options and design a solution that fits your property’s needs. Visit our landscape retaining walls service page to learn how our professional team can transform your property with a custom retaining wall built to last.