Why Building a Paver Walkway Transforms Your Property

Building a walkway with pavers is a rewarding DIY project that boosts your home’s curb appeal, creates a safe path through your yard, and adds lasting value. A well-designed paver walkway can solve problems like muddy patches and provide a beautiful, durable surface for years to come.

Quick Answer: The Basic Steps for Building a Paver Walkway

- Plan and design – Choose your paver style, pattern, and walkway dimensions (typically 36-48 inches wide).

- Excavate – Dig 8-10 inches deep, sloping away from your home at 1/4 inch per foot.

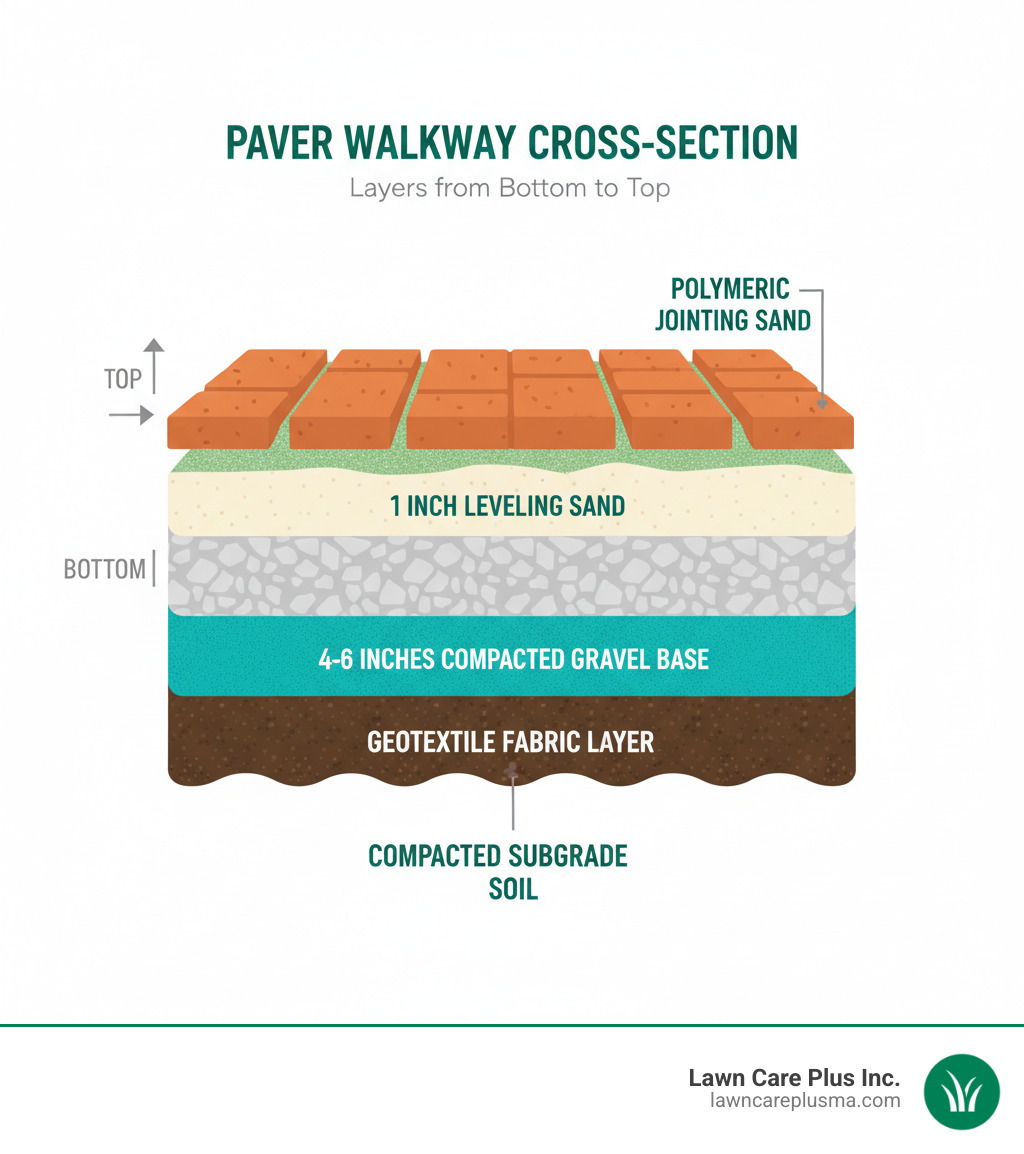

- Build the base – Add 4-6 inches of compacted gravel, then 1 inch of leveling sand.

- Lay the pavers – Place pavers hand-tight, tapping each with a rubber mallet to level.

- Finish – Fill joints with polymeric sand, compact, and mist with water.

The beauty of a paver walkway lies in its layered construction. Unlike poured concrete that cracks, pavers rest on a flexible foundation that moves with seasonal ground shifts. Pathways with pavers and gravel are also excellent for managing heavy rainfall, as water trickles between the gaps and stays on site rather than running off.

Whether you’re creating a charming garden path or a sturdy pathway to your front door, this guide walks you through every step. You’ll learn how to prepare the site, lay a stable foundation, install pavers like a pro, and maintain your walkway for years to come.

Building a walkway with pavers terms to know:

Planning Your Paver Walkway: Tools, Materials, and Design

Proper planning is the secret to a paver walkway that lasts for decades. Taking the time to choose the right materials, gather your tools, and set a budget will save you countless headaches down the road.

Essential Tools and Materials

Ensure you have everything you need before you start digging.

- Excavation & Prep: Round and flat blade shovels, wheelbarrow, rake, stakes, and string.

- Measurement & Leveling: Tape measure, level, line level, and a garden hose for outlining curves.

- Installation: Rubber mallet, hand tamper, and a plate compactor (available for rent at most hardware stores).

- Cutting: Paver saw with a diamond blade or a brick chisel and hammer.

- Safety Gear: Safety glasses, work gloves, hearing protection, and a dust mask are non-negotiable.

- Materials: Geotextile fabric, crushed stone base (3/4-inch), coarse bedding sand, pavers, edge restraints with spikes, and polymeric sand for joints.

Choosing the Best Pavers for Your Walkway

Your choice of paver defines the walkway’s character, durability, and cost.

- Concrete Pavers: Budget-friendly, versatile, and available in countless shapes, colors, and textures. They are durable and a great choice for most projects.

- Brick Pavers: Made from fired clay, they offer timeless charm and color that won’t fade. They are extremely durable and ideal for traditional landscapes.

- Natural Stone Pavers: Materials like bluestone, granite, or slate create a unique, premium walkway. Flagstone, with its irregular shapes, adds a rustic feel. This is the most expensive option.

- Permeable Pavers: An eco-friendly choice designed to let rainwater filter through into the ground, reducing runoff. They require a special open-graded base for proper drainage.

When choosing, consider how the pavers will complement your home’s exterior and local climate. For more inspiration, see these creative walkway ideas that will make your neighbors jealous.

Popular Paver Patterns and How to Choose One

The pattern you choose transforms the visual impact of your walkway.

- Running Bond: The most common pattern, with pavers offset by half. It’s simple, strong, and great for beginners.

- Herringbone: Pavers laid in a “V” shape at 45 or 90 degrees. It’s exceptionally stable and visually dynamic.

- Basketweave: Alternating pairs of pavers create a classic, woven look perfect for traditional settings.

- Jack-on-Jack (Stack Bond): Pavers are aligned in a clean grid for a modern look. This pattern is less stable and requires robust edge restraints.

In Massachusetts, running bond and herringbone patterns are popular for their classic New England look and durability in freeze-thaw cycles. For more design ideas, explore hardscaping 101: everything you need to know.

Calculating Materials and Budgeting for Your Project

First, calculate your walkway’s total square footage (length x width).

- Pavers: Check the manufacturer’s coverage per unit. Always add 5-10% extra for cuts and future repairs.

- Gravel Base: For a 6-inch base, multiply your square footage by 0.5 to get the cubic feet needed. Divide by 27 to convert to cubic yards.

- Bedding Sand: For a 1-inch layer, multiply your square footage by 0.083 to get the cubic feet.

- Jointing Sand: One bag of polymeric sand typically covers 50-100 square feet, but check the product’s specifications.

The cost of a paver walkway can range from $1,430 to $5,000 or more.

- DIY Route: Your costs are primarily materials and tool rentals. The total depends on your choice of pavers and other materials.

- Professional Installation: Internet averages suggest a range of $25 to $75 per square foot. This varies based on materials, pattern complexity, site conditions, and labor costs. These are not Lawn Care Plus Inc. prices—always request a custom quote for your specific project. A professional ensures quality, proper drainage, and saves you from the backbreaking labor. To understand the full scope of costs, see our guide on the cost of installing a new lawn, hardscaping, patios, walkways, and retaining walls.

The Ultimate Guide to Building a Walkway with Pavers

With planning complete, it’s time to get to work. This section guides you through the hands-on process of building a walkway with pavers step-by-step.

Step 1: Site Preparation and Excavation

This is the most critical phase for a long-lasting walkway. Start by marking your layout with stakes and string. For curves, a garden hose is useful for visualizing the shape. A standard walkway is 36 inches wide, while 48 inches allows two people to walk side-by-side.

Before you dig, always call 811 a few days in advance. This free service marks buried utility lines to prevent dangerous accidents.

Excavate to a depth of 8-10 inches. The walkway needs a slight slope for drainage—a pitch of about 1/4-inch drop per foot, sloping away from your home. Remove all sod, rocks, and roots. Once excavated, use a plate compactor to firmly compact the exposed subgrade soil. This creates a stable foundation for the layers to come.

Step 2: Laying a Stable Foundation (Base and Sand Layers)

A robust foundation is 80% of the job. First, lay down a layer of high-quality geotextile fabric over the compacted subgrade. This prevents weeds and keeps your base materials from mixing with the soil.

Next, spread your gravel base layer to a compacted depth of 4-6 inches. Add the gravel in 2-3 inch “lifts,” compacting each lift thoroughly with a plate compactor before adding the next. Ensure the base follows your planned slope.

On top of the compacted gravel, spread a uniform 1-inch layer of coarse bedding sand. To get this layer perfectly even, lay two 1-inch PVC pipes parallel on the gravel, spread sand between them, and use a straight 2×4 board to “screed” the sand level. Carefully remove the pipes and fill the voids. For more tips, our paver patio installation guide shares many of the same principles.

Step 3: Laying and Aligning the Pavers

Now for the satisfying part. Before laying pavers, install edge restraints along the perimeter, securing them with spikes into the gravel base. These are crucial for preventing pavers from shifting over time.

Start from a fixed edge, like a driveway or your house, to ensure your first row is straight. Gently place each paver onto the sand bed, fitting them hand-tight. Avoid sliding them, which disturbs the sand. Maintain a consistent joint space of about 1/8 to 1/4 inch.

As you lay each paver, tap it with a rubber mallet to seat it firmly. Periodically check for levelness side-to-side and front-to-back. Adjust by adding or removing small amounts of sand underneath. To avoid disturbing the sand bed, work from the surface of the already laid pavers.

Step 4: How to Cut Pavers for Edges and Curves

You will need to cut pavers for edges and curves. Safety is paramount: always wear eye and hearing protection, a dust mask, and gloves.

Mark your cuts clearly with a pencil. For straight cuts, a circular saw with a diamond blade or a wet saw provides the most precise results. Make several shallow passes rather than one deep cut to minimize chipping.

For curves, a wet saw is ideal. Alternatively, you can make a series of short, straight cuts and chip away the excess with a chisel and hammer. For minor adjustments, you can also score the paver deeply with a brick set and hammer, then strike it to break it cleanly. It’s efficient to save all your cutting for the end of the laying process.

Finishing Touches and Long-Term Care

These final steps lock in your hard work and ensure your walkway remains beautiful for decades.

Applying Jointing Sand to Lock Pavers in Place

The sand between your pavers is what holds everything together. While regular sand works, it can wash out and allow weeds. Polymeric sand is a superior choice; it contains polymers that harden when wet, creating a durable, flexible bond that resists weeds and erosion.

To apply, pour the sand over the dry walkway and use a push broom to sweep it into every joint. Work in multiple directions to ensure the gaps are completely filled.

Next, run a plate compactor over the entire surface. This vibrates the sand deep into the joints. You will see the sand level drop; sweep more sand into the joints and repeat the compaction process until they remain full.

Crucially, you must remove all excess sand from the paver surfaces. Use a leaf blower on a low setting or a soft broom. Any polymeric sand left on top will create a permanent haze when wetted.

With a clean surface, gently mist the entire walkway with a garden hose on a fine spray setting to activate the polymers. Avoid a strong stream, which can wash the sand out. Allow the sand to cure for at least 24 hours, keeping it dry as per the manufacturer’s instructions.

Walkway Maintenance and Troubleshooting Common Issues

A well-built paver walkway requires minimal maintenance.

- Cleaning: Sweep regularly to remove debris. A seasonal wash with a garden hose and stiff brush will remove ground-in dirt.

- Weeds: If you used geotextile fabric and polymeric sand, weeds should be rare. Pull any that appear immediately.

- Uneven Pavers: If a paver settles, it’s usually due to base issues. Carefully lift the paver and its neighbors, adjust the bedding sand to make it level, and reinstall.

- Water Pooling: This indicates a drainage problem. You may need to lift a section, regrade the sand and base layers to restore the 1/4-inch-per-foot slope, and reinstall the pavers.

- Re-sanding: Over time, joints may need fresh sand. For polymeric sand, you’ll need to clean out the old material before applying the new.

- Sealing: Sealing concrete pavers every 2-3 years can protect against stains and improve color. It is optional but recommended.

If you need help with maintenance or repairs, our hardscape service team can assist.

Special Consideration: Permeable Pavers and Drainage

For areas with drainage challenges, permeable pavers are an excellent solution. They allow rainwater to infiltrate through the surface into the ground, reducing runoff and recharging groundwater.

Installation differs significantly from traditional pavers. Permeable systems use an open-graded aggregate base—uniformly sized stones with large voids that allow water to flow through and be stored before soaking into the soil. This base is typically much deeper (12-18 inches) than a standard base.

Geotextile fabric is still used to separate the native soil from the stone base. Maintenance involves annual vacuuming or light pressure washing to keep the joints from clogging with sediment. For properties with drainage issues, the benefits are well worth the effort. Our masonry services near me experts can help you determine if this is the right solution for your property.

Frequently Asked Questions about Building a Paver Walkway

Here are answers to the most common questions about building a walkway with pavers.

How do you ensure proper drainage for a paver walkway?

Proper drainage is achieved by creating a consistent slope during excavation, typically a 1/4-inch drop per foot, directing water away from your home. The layered construction of a compacted gravel base and sand bedding also allows water to filter through. In areas with significant drainage concerns, permeable pavers are specifically designed to manage stormwater by allowing it to pass directly into an open-graded base below.

What are the main challenges when building a paver walkway?

The biggest challenges for DIYers are:

- Achieving a stable base: This requires meticulous excavation, leveling, and thorough compaction with a plate compactor to prevent future settling.

- Cutting pavers accurately: Making precise cuts for edges and curves requires the right tools (like a paver saw) and practice.

- Preventing weed growth: Using high-quality geotextile fabric under the base and polymeric sand in the joints is the best defense against weeds.

- Physical labor: Excavating soil and moving tons of gravel and sand is strenuous work. Be realistic about the physical demands of the project.

Can I build a paver walkway on a slope?

Yes, but the method depends on the steepness of the slope.

- For gentle slopes, you can generally follow the natural contour of the land while maintaining the necessary 1/4-inch-per-foot drainage slope across the walkway’s width.

- For steeper slopes, you must build a terraced walkway with steps. This involves excavating level landings into the hillside and connecting them with short runs of paver stairs. Each step requires a riser (made from retaining wall blocks or treated lumber) and a stable, compacted base behind it. This is a more advanced project that requires careful engineering to ensure stability and prevent erosion. If your property has a significant slope, consulting a professional is highly recommended.

Conclusion

You now have a complete roadmap for building a walkway with pavers. This project is an achievable way to add significant curb appeal, function, and value to your property. A well-built paver path can solve drainage issues, eliminate muddy spots, and provide a beautiful entrance to your home for decades.

The key to a long-lasting result is a solid foundation. By taking the time to properly excavate, compact your base, and ensure proper drainage, you are setting your project up for success.

However, we understand that this is a labor-intensive project. Excavating soil, hauling gravel, and laying pavers is hard work. If the scope of building a walkway with pavers feels overwhelming, or if you simply want the peace of mind that comes with a professional installation, the expert team at Lawn Care Plus Inc. is ready to help.

We have years of experience creating beautiful, durable walkways throughout the Boston Metro-West area. We can handle everything from simple paths to complex terraced walkways on sloped properties, delivering a high-quality result efficiently.

Whether you tackle this project yourself or bring in our team, you’re making a smart investment in your property.

Contact our walkway installation experts today! We’re here to provide a custom quote and turn your vision into a reality.